Thermal Performance of Mass Timber Constructions in the Field

A thermal assessment of large mass timber cubes with various wall thicknesses, heating systems, inner and outer conditions, and comparison of results to lightweight frame wall cubes.

The Background Information

The International Mass Timber Alliance (IMTA) has partnered with Oak Ridge National Laboratory (ORNL) to assess the thermal performance of mass timber CLT (cross-laminated timber) walls.

Phase 1 of the study investigated the heat flux through individual panels of CLT under various exterior climatic conditions. Our Phase 1 article presents the findings of the study. Phase 2a of the study investigated the thermal performance of CLT walls in a small cube within a climate simulator. Our Phase 2a article presents the findings of the study.

Phase 2b of the study is scheduled for 2024 and will assess the thermal performance of CLT walls in larger cubes placed outside in three different climate zones.

Phase 2b: Study of Large Cubes on Remote Sites

The Phase 2b study will evaluate how maintaining thermal comfort, rather than a fixed air temperature, can contribute new data on energy savings in mass timber buildings. It is anticipated that this approach will support a reduction of the required wall thicknesses of mass timber buildings, potentially lowering the overall embodied carbon of the structure. Ultimately, the research will support the decarbonization of buildings by supporting the use of mass timber in building construction.

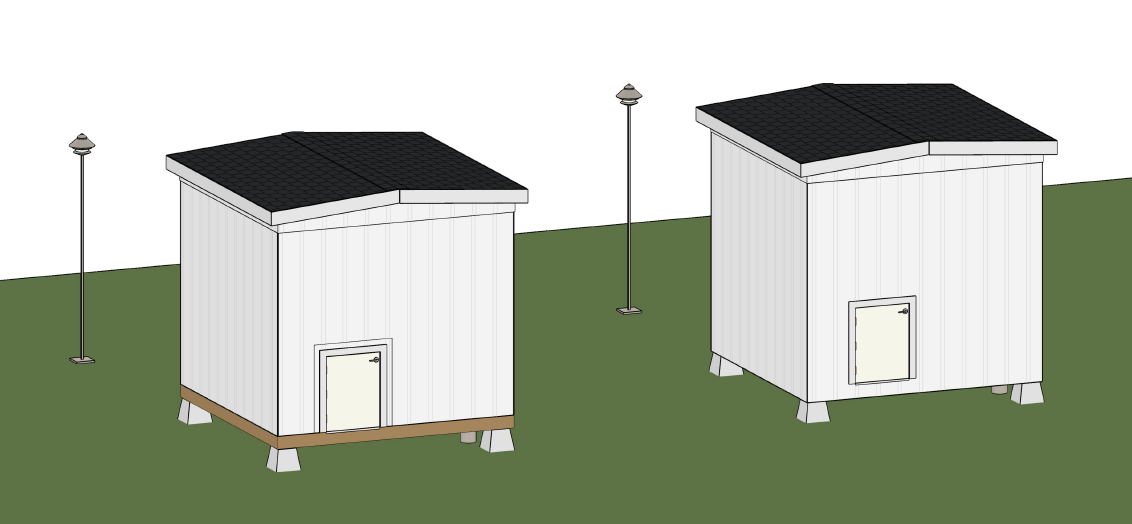

Figure 1. Custom-designed, prefabricated CLT panels.

Figure 2. Assembled CLT cubes.

Cube Construction & Instrumentation

The cubes are being built as described in the Phase 2a article but scaled to a three-cubic meter (3 m) size. The LW frame cubes will be built according to the building code of the test location. The CLT panels were prefabricated and provided to IMTA for cube construction (Figures 1 and 2).

The instruments installed in each cube are the same as those used in the Phase 2a study:

- Heating units

- Sensors

- Control units

Field Test Conditions

One 3 m CLT wall cube and one LW wall cube will be placed at each of three climate zones:

- Oak Ridge, TN (mixed-humid climate zone)

- Golden, CO (very cold climate zone)

- Nacogdoches, TX (hot and humid climate zone)

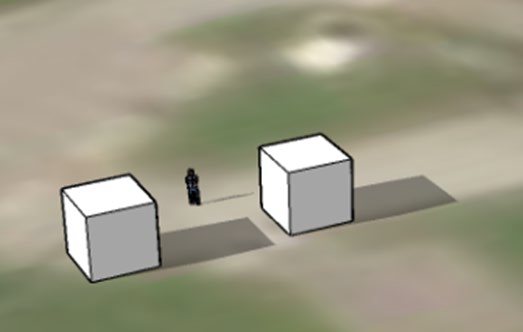

The cubes will be placed 20 feet apart to avoid shading each other, as shown in Figures 3 and 4.

Figure 3. Three-meter cubes placed 20 feet apart outside at test sites.

Figure 4. Shading on cubes at noon in December in Knoxville, TN.

The cubes will be evaluated under different temperature control modes and heating modes. The temperature control modes will be:

- Control for fixed indoor air temperatures (e.g., 72°F for heating and 75° F for cooling).

- Control for occupant comfort based on operative temperature. The operative temperature is the average of air temperature and the mean radiant temperature from surfaces to which the occupants are exposed.

The heating modes will be convective heating (i.e., heated air only) and radiant heating (i.e., providing radiant heat to the surfaces and occupants inside the cube). All cooling will be convective using a mini-split heat pump system.

The cubes will be monitored over 24 months for the following parameters:

- Indoor air temperature

- Operative temperature

- Air humidity

- Heating/cooling energy use

- Heat fluxes through the walls on the interior surface

- Temperature and humidity at the interfaces between material layers in the walls

The data will be continuously transmitted to ORNL for collation and evaluation.

Phase 2b Data Analysis

The study data will be used to validate energy, thermal, and moisture models (e.g., EnergyPlus™ whole building energy simulation program, WUFI® Plus heat and moisture simulation program, etc.). The validated modeling will then be used to extrapolate the cube results to whole buildings in different climates. The results will allow the evaluation of building envelope criteria for CLT walls compared to LW walls.

ACKNOWLEDGMENTS

The information presented here was originally published in April 2022 by ORNL Staff of Mikael Salonvaara, Emishaw Iffa, Andrè Desjarlais and Jerry Atchley under CRADA NFE-20-08326.

This project was carried out in partnership with the International Mass Timber Alliance (IMTA) who provided the test panel assemblies. Mr. Robert Pickett, IMTA secretary, and Dr. Carl Manz, CT Manz Consulting, Inc. provided technical support to the project.