Getting Log and Timber Homes Up to Code

Log and timber homes present unique challenges, especially when it comes to proving their energy efficiency. Energy codes being drafted now are tailored for conventional home-building techniques and don’t take into account the thermal mass properties of wood.

Together, let’s prove log and timber homes have a place in a sustainable future and can meet strict energy codes. Help us advocate by becoming a board member or make a donation to fund testing and data collection. Every little bit helps inch us closer to securing the future of the log and timber industry.

Read on to learn more about how the thermal mass performance of mass timber affects its energy efficiency and what’s at stake for the log and mass timber industries.

Or help us champion this vision by joining our board or through donations to support further testing. Your action makes all the difference.

Thermal Mass Performance of Log & Timber Structures

As many of you know, wood is a natural insulator and ideal for an energy-efficient design. According to Naturally Wood in Canada, “it’s adaptable to virtually any climate, can be tailored to handle wind and snow loads, and is a natural insulator reducing heating and cooling costs. Softwood has about 10 times the thermal insulating ability of concrete and masonry, and 400 times that of solid steel.”

Those stats are impressive, but today’s energy codes are being built around R-values and log homes don’t meet the building codes by these standards. Why? Insulation products are certified and labeled for R-value, representing the conduction of heat through the material. Solid wood is not a labeled product. It also adds the benefit of thermal mass.

The standard being developed under the R-value measurement would require a 14-inch log or timber wall, making log home construction too expensive for most people. Instead of buying their dream log home, they’ll turn to traditional-style homes to save on building and perceived future energy costs if they look at the R-value only.

As a result, log home contractors and builders may be priced out of the market by cheaper conventional-style homes that meet a more conventional energy standard.

Testing is needed now to stay competitive in the marketplace and prove that log and timber homes are a beautiful alternative to traditional home construction and a sustainable and green alternative.

Proving log homes thermal mass performance is the key to securing the future of the log and timber home industry.

Why Focus on Thermal Mass Performance?

Imagine, if you will, a wood stove burning in a cozy log home on a snowy winter day. When you touch the interior wall next to the stove, it feels warm to the touch.

Now walk outside, and put your hand on the exterior side of the wall. Odds are you won’t be able to tell where the wood stove is, and the exterior wall feels cool to your hand. It’s cold outside, so you head back in. The fire dies now into the evening, and the temperature goes down outside, but the interior wall is still warm. It gradually releases the warm energy it stored from earlier in the day back into the room to keep you warm and comfortable at night. The wood acts like a thermal battery.

Testing the thermal mass of log and timber homes is essential to securing the future of the entire log home industry. Several states and the federal government aim to be carbon neutral by 2050. They intend to accomplish this by regulating everything that consumes energy—including housing.

If we don’t do something now, it won’t be long before a twelve-inch-wide log or mass timber will not meet the “R-value” requirement of a wall in an individual structure. Our industry needs to change. We must move log and mass timber homes away from “R-values” and into thermal mass. IMTA’s efforts are the first significant step in making this change.

Next Steps: How You Can Help Secure the Future of Log and Mass Timber Homes

The IMTA received a grant from the U.S. Department of Energy (DOE) to work with Oak Ridge National Labs (ORNL) in Tennessee to test the benefits of thermal mass in log homes.

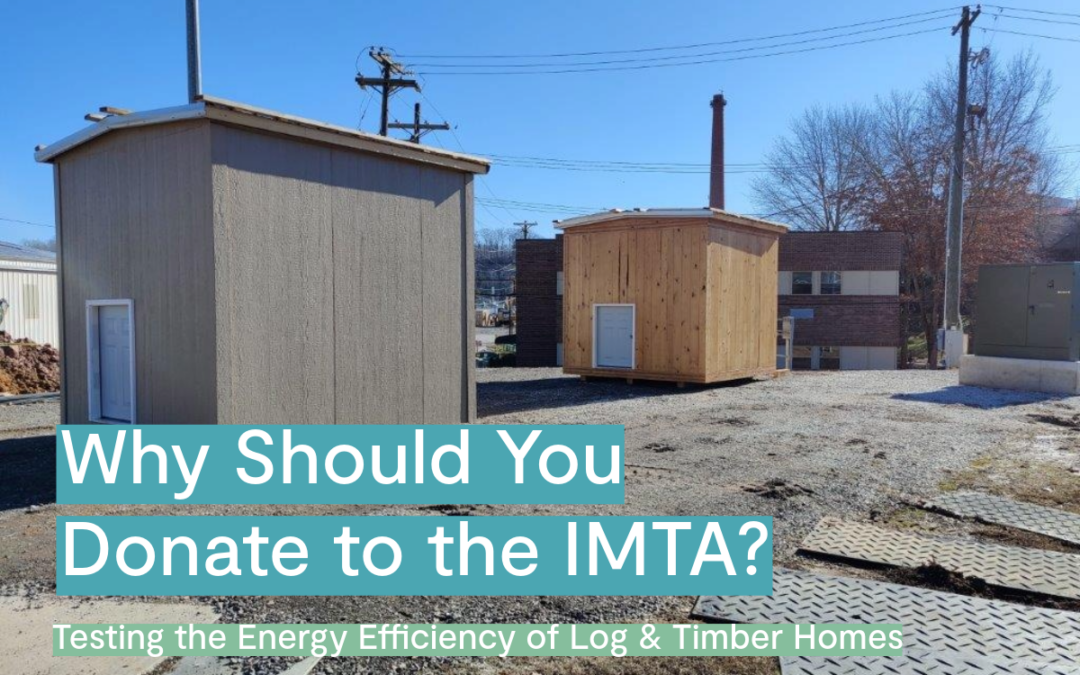

The next step in testing is constructing ten-foot by ten-foot cubes of solid wood and standard construction in Texas, Colorado, and Tennessee to prove the laboratory results and verify the models. Fully instrumented, the cubes will be exposed to a natural environment for two years.

We are Running Out of Time

To continue testing, we need the cube experiment to be completed by the summer of 2026 to have the data summary ready for the next significant code update in 2027. On top of this, all our DOE grant money has been spent.

$100,000 is needed to build the six cubes and collect the two-year data required to prove the efficiency of log and timber structures. We aim for twenty log home manufacturers to contribute $5,000 each to continue testing.

Together, let’s prove log and timber homes have a place in a sustainable future and can meet strict energy codes. Help us advocate by becoming a board member or make a donation to fund testing and data collection. Every little bit helps inch us closer to securing the future of the log and timber industry.

ACKNOWLEDGMENTS

The information presented here was originally published in April 2022 by ORNL Staff of Mikael Salonvaara, Emishaw Iffa, Andrè Desjarlais and Jerry Atchley under CRADA NFE-20-08326.

This project was carried out in partnership with the International Mass Timber Alliance (IMTA) who provided the test panel assemblies. Mr. Robert Pickett, IMTA secretary, and Dr. Carl Manz, CT Manz Consulting, Inc. provided technical support to the project.