The International Mass Timber Alliance (IMTA) partnered with Oak Ridge National Laboratory (ORNL) to compare and assess standard framed wall components to mass timber CLT (cross-laminated timber) components. Thermal performance testing was performed on various thicknesses under varying climate conditions in a test chamber.

The Background Information

IMTA did initial testing at the world-leading research center ORNL in Oak Ridge, TN. Established in 1943 as part of the Manhattan Project, ORNL is building a legacy of discovery and innovation by addressing our most urgent R&D needs—energy and national security.

Starting in November 2020, IMTA began working formally with ORNL to secure the future of mass timber in the coming energy revolution.

The project studied the thermal performance of mass-timber (CLT) structures compared to standard framed systems. This project also pre-assessed the thermal performance of lightweight insulation when subjected to infrared radiation (sunlight).

ORNL and IMTA gathered and reviewed literature on the thermal performance of mass timber. This study then used building heating and cooling energy simulations to show thermal performance benefits (total energy, peak demand) when mass-timber is substituted for standard framed systems.

Meanwhile, ORNL staff ran simulated wall assemblies with the COMSOL Multiphysics Software (COMSOL). The software evaluated the simulation model performance and established material parameters of the EnergyPlus v9.6 (DOE 2021a) whole-building simulation model. Simulations were carried out sequentially in both winter and summer climate conditions.

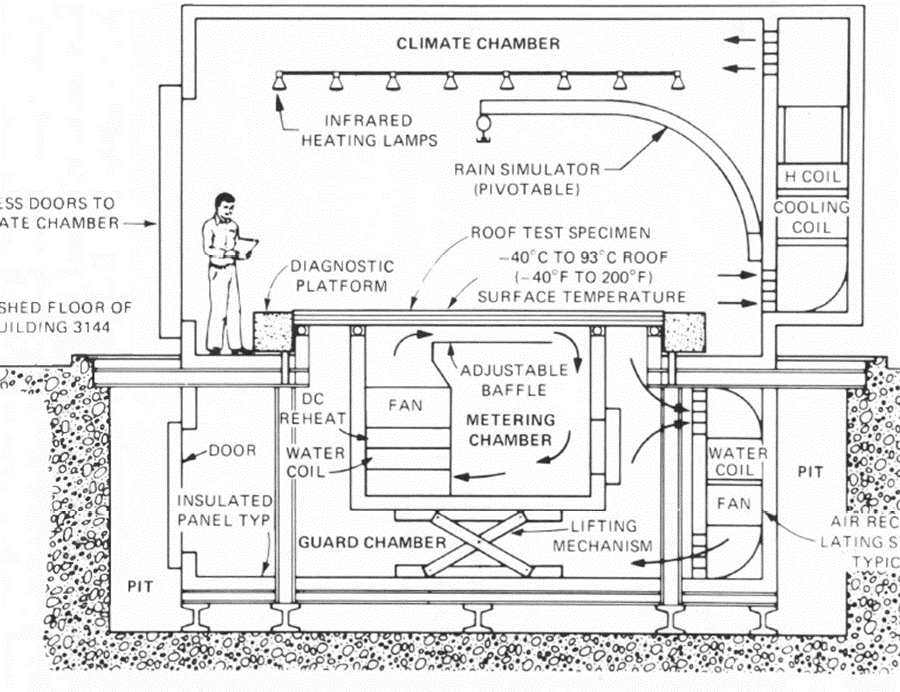

This study first builds an analytical model of the methods and materials used and then tests an actual sample complying with those methods and materials. ORNL used its Large-Scale Climate Simulator to validate the model and test thermal impact on the wall assemblies. (A sketch of the chamber is below.)

Why Test Cross-Laminated Timber?

Thermal mass is the ability of a material to absorb, store, and release heat. It moderates indoor temperatures when optimized, allowing heating, ventilation, and air conditioning (HVAC) systems to operate more efficiently during peak hours.

Cross-laminated timber (CLT) and other mass wood products are lightweight and sustainable building materials in comparison to concrete. However, the influence of CLTs on heating and cooling, peak energy demand, and indoor climate control isn’t well documented.

Building codes continue to evolve to meet future energy demands. Current CLT design ignores the thermal mass benefits and focuses only on structural and fire issues. This IMTA project seeks to identify and scientifically prove the energy efficiency benefits of CLT and mass timber structures.

The Test Plan

The test was designed to—

- Demonstrate the thermal mass impact of mass wood walls on heat flux through the wall during daily weather cycles.

- Validate simulation models, enabling further expansion of the performance to actual buildings in different climates.

The Testing Objectives

- Scientific Efficacy: Test the thermal performance of insulated mass wall structures in controlled laboratory conditions.

- Validate Simulation Models: Move from simulation models to validate the information under varying climate conditions.

- Isolate the Impact of Wood’s Thermal Properties: Learn how thermal mass, conductivity, and moisture storage all affect heating and cooling energy efficiency

- Optimize the Performance: Take what we learn and optimize the performance of mass timber and CLT.

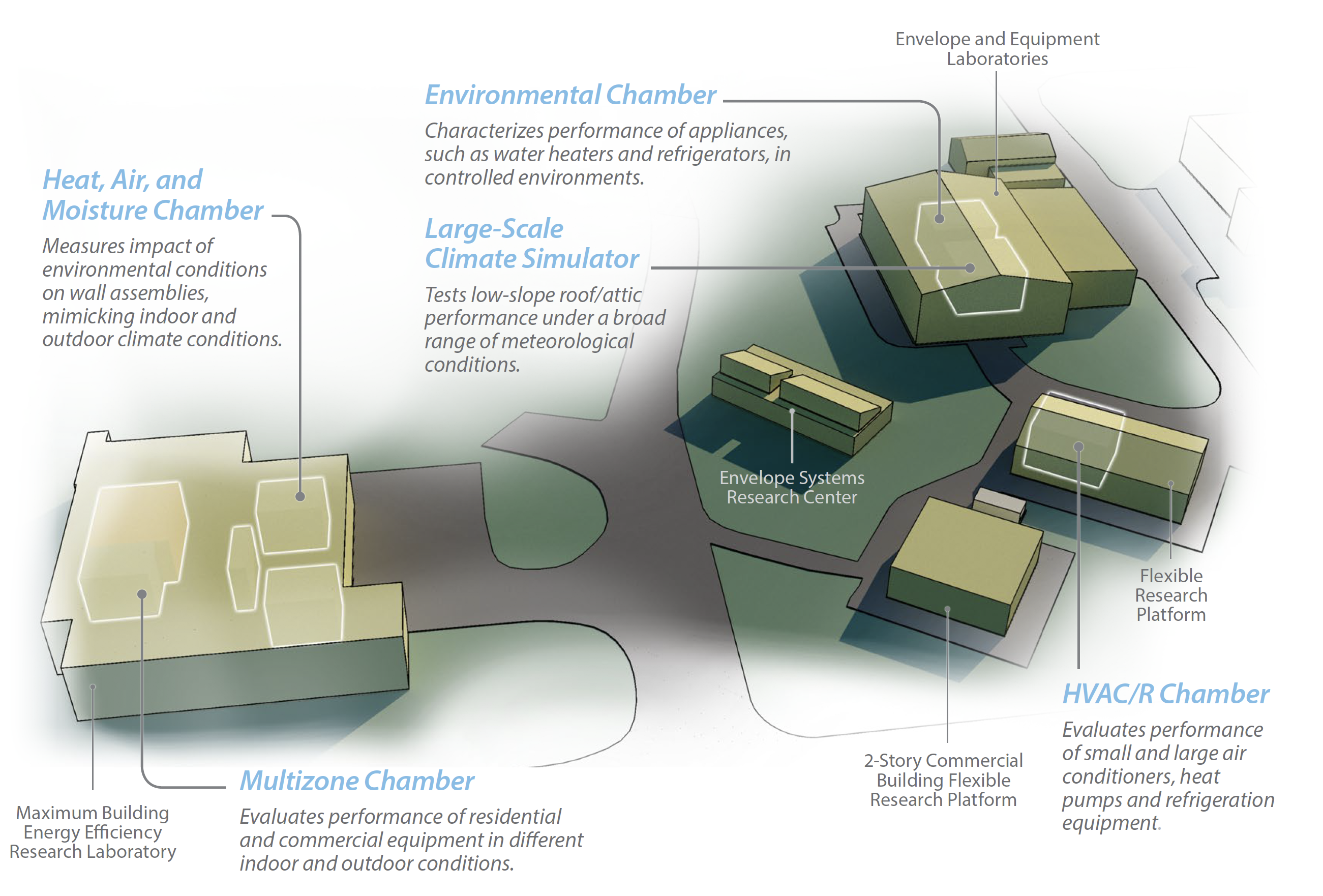

The map above represents the Oak Ridge National Labs campus and facilities. IMTA did Phase I and 2a tests in the

Large-Scale Climate Simulator.

Diagram of the Large-Scale Climate Simulator

The Test Procedure

The IMTA expedited the materials and assembled the panels to be tested. They included the following:

- 2×4 Lightweight, ½ inch Gypsum board. R13 batts, studs at 16 inches on center (3.5-inch cavity), 7/16 inches OSB.

- 2×6 Lightweight, ½ inch Gypsum board. R23 batts, studs at 24 inches on center (5.5-inch cavity) 7/16 inches OSB

- 4-inch CLT ½ inch Gypsum board,.4-inch CLT

- 6-inch CLT ½ inch Gypsum board. 6 3/4 inch CLT

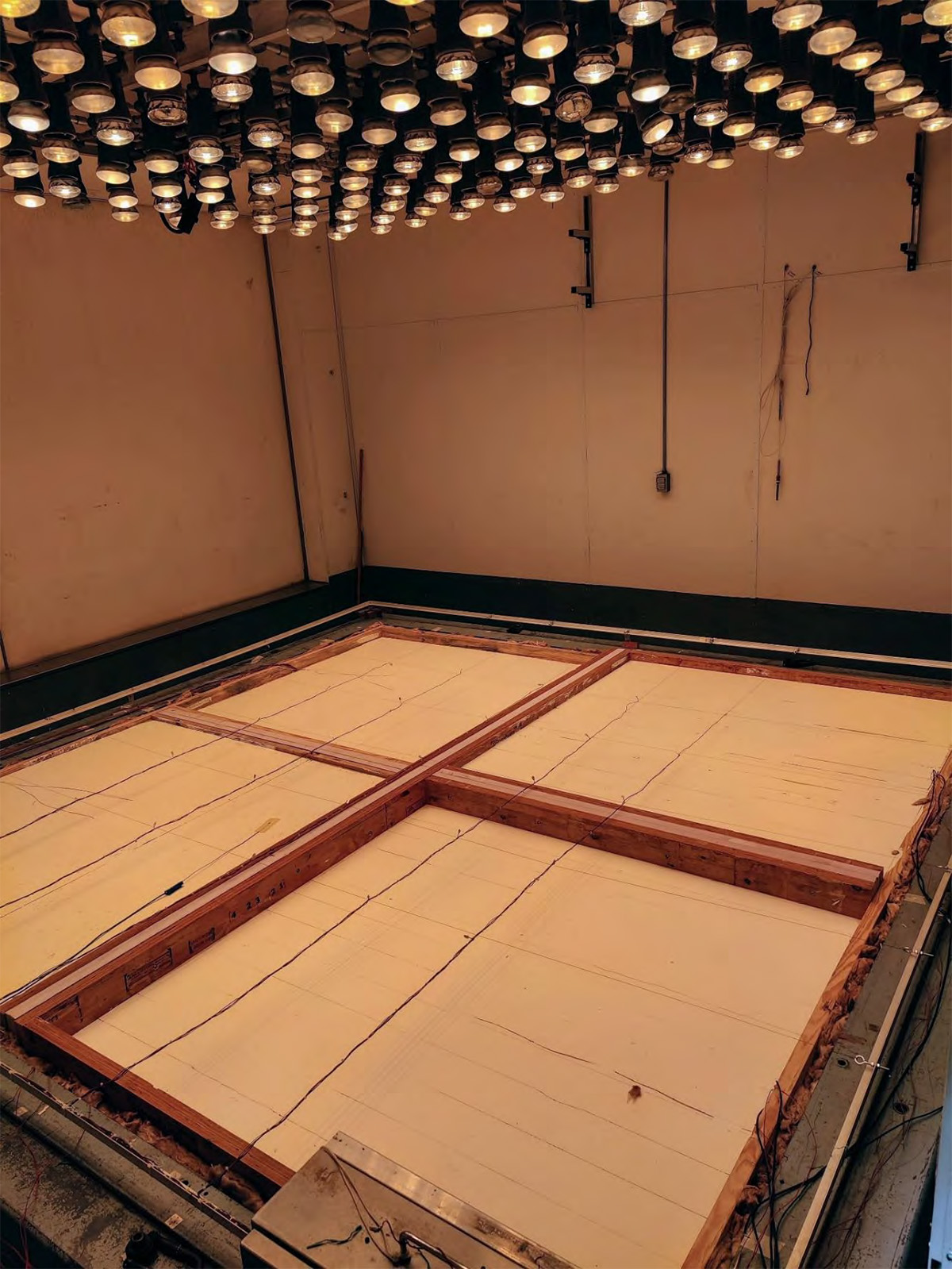

As shown below in the photo, the walls were installed horizontally on a frame lifted into the chamber. Then, each wall section was separated by two inches of extruded polystyrene insulation so the panels could be tested under the same conditions.

The outdoor (upper) test chamber performs a 24-hour hourly outdoor weather condition test simulating temperature, solar radiation, etc. The test is repeated for several days until the same response happens daily.

The indoor (lower) climate chamber conditions were fixed at 72°F (22°C) and 50%-relative humidity and continuously monitored the walls’ temperatures and the heat fluxes on the exterior and interior surfaces. The results from the laboratory testing help validate and fine-tune the simulation models—allowing us to expand the results to multiple dynamic scenarios. The experiment will focus on cooling demand in buildings.

The Test Analysis and Conclusions

Following the tests, ORNL staff expanded the laboratory test results from the wall system level to the whole building level to analyze the potential of mass wood structures to impact buildings’ heating and cooling demand. They used DOE’s entire building simulation model EnergyPlus to evaluate the hourly energy use for heating and cooling mass wood assemblies in three climate locations (hot-humid, mild, cold). They found that the inclusion of mass wood walls in a residential building has a positive impact on energy savings, peak demand reduction, and comfort conditions in three climatic regions in the US.

The simulations of the laboratory tests confirmed that the model and model parameters in dynamic conditions are representative of the actual thermal performance of the lightweight and mass wood wall assemblies. The multidimensional lightweight wall assembly was developed to a 1D representation with the same thermal performance to use the assembly in EnergyPlus.

Simulations were then performed in three IECC climate zones (location): 2A (Houston, TX), 3B (Los Angeles, CA), and 5B (Golden, CO). The DOE prototype building was used as the baseline, with the exterior wall assemblies slightly modified to meet the International Residential Code (IRC) 2021 requirements for lightweight wood frame and mass timber walls.

The IRC 2021 building code for the building envelope has two paths: U-factor requirements and the R-value alternative (Table 3).

Table 3. IRC 2021 Building Envelope Requirements

* The code states that mass timber is considered a mass wall. Any wall with a heat capacity greater than or equal to 6 Btu/ft2,°F is also considered a mass wall.

**For example, R-4/R-6: first value (4) applies when more than 50% of insulation is on the exterior side of the wall; second value (6) applies if over 50% of insulation is on the interior side.

The simulation results show the significant thermal inertia impact of mass timber wall assemblies on annual energy use—especially on the peak demand as compared to the standard 2×4 and 2×6 lightweight wall systems. Annual energy savings with mass timber walls, as compared to the baseline light walls (depending on the climate zone) were up to 22%. The exception was the solid mass wall, which had a 72% higher U-value than the baseline wall, which had 12% higher heating and cooling energy use in Golden, CO. In addition, the lightweight walls with extreme insulation levels (R-100 continuous insulation) saved less cooling energy than the mass timber walls.

The results show that if the focus is on lowering the cooling energy use, use thermal mass to solve the problem rather than adding additional insulation. In climates with significant variations in diurnal temperatures, adding thermal mass can most actively balance heat flows. The thermal benefits are less pronounced in environments that have cold climates with long winters. Thermal mass can even provide shelter from extreme temperatures during power outages by maintaining the indoor temperatures in a building. This aspect of thermal mass was not included in the study.

Mass timber walls efficiently shifted heating and cooling energy demand away from the peak demand hours, thus helping the power grid. As a result, the peak demand for heating and cooling was 30%–50% lower with mass timber, depending on the month and location. Based on the simulations, mass timber walls can also improve thermal comfort by reducing occupants’ time in uncomfortable conditions by up to 46%.

What’s Next for IMTA?

Our research will continue in a follow-up project to evaluate how thermal comfort can contribute to new findings associated with energy-saving in mass timber buildings by maintaining thermal comfort inside the living space instead of applying fixed temperatures. This could reduce the required wall thicknesses of mass timber buildings, thus lowering the embodied carbon overall. Ultimately, the research will support the decarbonization of buildings by supporting the use of mass timber in buildings.

ACKNOWLEDGMENTS

The information presented here was originally published in April 2022 by ORNL Staff of Mikael Salonvaara, Emishaw Iffa, Andrè Desjarlais and Jerry Atchley under CRADA NFE-20-08326.

This project was carried out in partnership with the International Mass Timber Alliance (IMTA) who provided the test panel assemblies. Mr. Robert Pickett, IMTA secretary, and Dr. Carl Manz, CT Manz Consulting, Inc. provided technical support to the project.